AckSed

-

Posts

356 -

Joined

-

Last visited

Content Type

Profiles

Forums

Developer Articles

KSP2 Release Notes

Bug Reports

Posts posted by AckSed

-

-

Good launch, though the camera on the second stage wasn't enjoying it. For a moment, I thought the rays from the sun were hot-spots on the engine bell, but no.

-

Hey, a sparkly new first stage!

-

Honeybee Robotics developing a solar

stick insectmesh networksurveillance towerstreet lightALL of them: https://www.honeybeerobotics.com/news-events/honeybee-robotics-to-develop-lunarsaber-for-darpas-luna-10-program/ -

Since we're on the topic of batteries, Energy Dome has my vote. It's supremely simple: use the properties of carbon dioxide to avoid the expensive cooling of liquid-air energy storage. Take a gasbag (already used in the biomethane industry), fill it with CO2; use renewable energy to compress the CO2 into liquid tanks, storing the heat of compression; when you need the electricity, open a valve and let the room-temp liquid CO2 expand through a turbine and back into the gasbag. Nearly all of this is off-the-shelf tech, too.

I must also give a shout out to ESS Inc.'s iron flow battery, and the startup Aquabattery's acid/base table salt battery. Both offer 12-hour storage which, believe it or not, is close to being enough to smooth out a solar/wind mixture's intermittency. They're also utilising non-toxic, easily-acquired materials.

-

It does sound good, and more cheap batteries for renewable storage, with a company behind it producing them, is always a good thing.

I have one point of contention... two points. The need to keep things liquid, and the use of antimony.

The liquid metal will need heating. My naive trawl of Wikipedia says that antimony melts at ~630 °C, calcium metal melts at 842 °C and calcium chloride ~775 °C. When Ambri reassures customers that the external surfaces of the insulated shipping-container units are "safe-to-touch", you know it's hot in there. Their site says that the units are "self-heating", which only means that it doesn't require external sources of heat; it has heating elements in each tray of cells. There may be natural resistance there too, I don't know. That is extra power needed before every charging cycle. It may not be much, as insulation these days can be extremely good, but it's there. If it draws from its own reserves, that is a parasitic load.

One key element that could mitigate this is the classic duck curve of solar, where you overproduce during the day. Divert that to heating during charging and you're good. Indeed, it's advertised as ideal for daily deep-cycling, and in this regard, it absolutely is. Round-trip efficiency might be a bit lower than advertised, though.

The antimony gave me pause because while it's less toxic than arsenic, its dust is not healthy. The individual sealed cells being built out of stainless steel does address this; they aren't just buckets of metal open to the air. The manufacturing side may be the only real risk to health, and that can be mitigated.

Dug out the patent: "Multi-element liquid metal battery" (2021), Pat. num.: 16/193,405.

tl;dr looks good. The patent describes a liquid or partially-liquid metal battery, which lowers the heating requirements somewhat, using a host of different non-ferrous/alkali metals. It describes the calcium-antimony operating at 550 °C. Energy efficiency for that one was hovering around 72-73%, with a near-perfectly horizontal line on the graph of coulombic efficiency (how much a cell loses capacity over time) and energy efficiency plotted up to 40 cycle counts. Other configurations were tested to 1400 cycles with the same horizontal lines.

Interesting notes: the calcium alloy is 90% Ca, 10% magnesium, and the electrolyte has, at least in the patent, lithium chloride in addition to calcium chloride. One wonders how much or little they use of the LiCl (noting that even Li-ion batteries don't use that much).

-

My ears pricked up when I saw "phosphate". From what I read, phosphorous is an uncommon element in the Solar System, but to see it on samples from a carbonaceous asteroid (around 75% of all asteroids) is promising for human ISRU in space.

-

Two things I noticed: one, the pieces flying off the heatshield were a bit alarming, but it was an ablative heatshield. Two, a few bits of paper or something clung to the window and seemed to scorch an outline on the window during the first re-entry. It wasn't on the outside as the ocean landing essentially washed the window, and the scorch mark was still there. How hot was that window inside?

-

In summary:

Observations funded until 2028-29;

Arrokoth was, it seems, made up of 8-9 smaller objects glomming together gently enough they didn't break;

Computing possible Kuiper Belt Objects to observe has been hugely sped up from weeks to hours, thanks to computer-aided selection;

There are a series of sensors that detect the infinitesimal amounts of dust at the edge of the Kuiper Belt. It was predicted it would fall off around 40-50 AU, but it hasn't yet;

Using the small LORRI telescope, they took observations of Uranus and Neptune from a brand-new perspective. They also observed on the blackest part of the sky they could find to measure the Cosmic Optical Background, the remaining visible light in the cosmos. It turned out to be brighter than expected, even when they eliminated everything they could think of. They're going to check 15 more fields of utter blackness to see if this holds water.

-

6 hours ago, DDE said:

That doesn't exactly scream "affordable seat structure material".

All right, I'll exert the effort as well as sharing a cool thing.

Yttrium's market price per kg is 33 USD, or $33,000 per metric ton.

It's a by-product of rare-earth processing, and there's a dedicated supply chain because it is used in some catalysts and as a dopant for laser gain mediums. Looking at the patent reveals that the amount needed to make it fireproof is 0.05-0.6%. If I assume this is by weight, then in an alloy of 95% Magnesium (~$3,000 per metric ton), 0.15% Calcium (~$9,900 per metric ton of metal) and 4.8% Zinc (~$2,900 per metric ton), 0.05% Yttrium adds roughly $1650 to the price of a metric ton.

Mash those other numbers together:

95% of 3000 = 2850

0.15% of 9900 = 14.85

4.8% of 2900 = 139.20

2850 + 14.85 + 139.20 + 1650 = $4,654.05 USD per metric ton

Now, this fire-proof, corrosion-proof wonder-alloy (we'll call it AirMag) is pricey, no question. A normal AZ91D magnesium alloy is $3,100 USD per mt. But remember our weight savings - 20-25% over aluminium alloys. Taking into account rising airline fuel costs and the built-in fire-safety, it may close as a 'spend money now to stop spending money later' business case. Let's work it out.

I don't know how much airline seats weigh. We will assume the framework of each one is 5kg and made of aluminium alloy. An Airbus 380 hovers around 460-510 seats depending on airline. It also burns 11-12 metric tons of fuel per hour, for $816 per mt at UK 2022 prices. That's $8,932-9,744 USD per hour. (Fuel isn't cheap here.)

If we take 500 seats as a round number, that's 2.5 mt just in seats.

Using AirMag we save 20% of the mass, or 500kg, for approximately 3 times the price.

Every kg we save in airplane weight saves 0.02-0.03 kg of fuel per 1,000km.

QuoteTo reduce the cost per available seat kilometre (CASK) of ~6 €cent by 1 ‰, the weight needs to be reduced by ~300 to 1,000 kg (structural or operational), depending on the aircraft type.

So although we're on the right track regarding weight savings, that's just 10-15kg of fuel or $8.12-12.18 saved per 1000km flight in fuel.

Now I don't know whether this margin would be an acceptable trade, but I've already spent two hours on this so I will admit that for airlines, it's weak. Not insignificant, as airliners cost a bundle, and depending on fuel prices, carbon emissions and under differing circumstances a campaign of lightweighting on the seats would be a drop in the bucket compared to the millions spent on building the things. But a retrofit would need a better salesman than I.

-

tl;dw Magnesium alloys have advanced significantly in fire-resistance and corrosion resistance, and new casting techniques from Idra are in development that allow for large castings to be made, reducing weight by up to 25% on all sorts of things - electronics, phones, cars, airplanes, non-structural rocket parts.

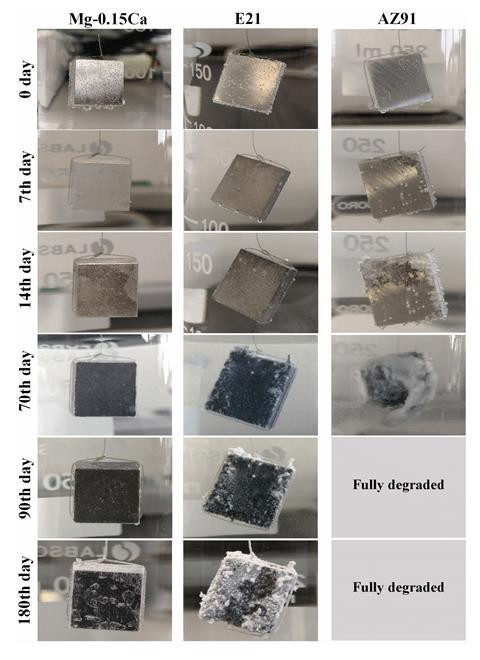

The cool thing is that the same element that gives corrosion resistance to magnesium - calcium - is also one of the three that gives fire resistance. An alloy of pure Mg with 0.15% of Ca survived 180 days of submersion in saltwater that was 3.5% NaCl by weight, with minimal degradation. That's it. That's all you need to make a lightweight metal resistant enough they nicknamed it "stainless magnesium":

Spoiler

E21 (Elektron 21) and AZ91 are aerospace Mg alloys.

The addition of zinc and calcium, with yttrium, gadolinium or ytterbium added in trace to marginal quantities, grants the other alloy in the video its ability to melt before it ever catches fire. In fact, it is even approved by the FAA for use in seat structures. They tried to light it in an oil fire and it melted after 60+ seconds, yes, but plain would not burn.

Finally, Idra's thixotopic shot casting (chunks of the magnesium alloy are kept somewhat below melting point and, like plastic, forced into the mould with a screw) allows for big parts to be made in one shot. They also release from the mould much easier than aluminium parts.

-

I wonder if there was a cryogenic propulsion stage in there?

-

Stumbled on some minor forgotten lore regarding LOX-cooled rocket engines.

The Russians were really good at this, though the only one I know of for sure is the American Launcher Space's (now Vast's) E-2 kerelox staged-combustion engine... which had a Russian designer on the team.

The US, though, seemed to take it as read that you just shouldn't use LOX to cool. But it seems that didn't stop NASA experimenting. I found a photo in an archive of a small, LOX-cooled engine chamber and nozzle: https://nara.getarchive.net/media/lox-liquid-oxygen-cooled-engine-jet-at-the-rocket-engine-test-facility-retf-8c2f44

The photo was taken in 1979. Some more digging indicated a 1980 experiment where kerelox was introduced: https://nara.getarchive.net/media/liquid-oxygen-cooled-lox-rp-1-rocket-engine-48d37b

Aaaand that's where my trail ends. I can't even find a paper. So far as I know, the experiment was small enough that it didn't make any waves and rocket engineers continued to declaim LOX for cooling.

-

Here's a site to browse (archive.org because the images would be otherwise broken): Introduction to Future Launch Vehicle Plans

From the archives of sci.space.tech: Fuel Table

A piece of the puzzle of the lack of rapid reuse on the Shuttle was the culture. The example I remember is the stripping down of the RS-25: they could probably have gotten away with less invasive inspections and increased the lifetime and reliability of the engines if it hadn't, but they had already gone to the trouble of installing the process, and no-one would or could argue for less caution on one of the most complex systems ever flown. So they were stripped down and rebuilt after every flight, even if nothing was wrong.

Liquid-fuelled boosters, first flyback then sea-landed, were proposed and would also have assisted in reusability, but the compromises were already settling in even as the 70s dawned. The military's experience with solid rockets was always in the background. They could be stored! They were safe to handle! They gave a kick to all sorts of early rockets at just the right time. Telling Thiokol "no" would have made it a better reusable vehicle but also extended the development. No-one was making the F-1 any more, though the expertise was still around, and there was an improved, simplified F-1A under design when Saturn V production was shut down in 1968. (Yes, it was shut down before Apollo 11.)

Methalox was just not seriously considered for most of the US space program (Ignition! only gives it a passing mention), though propalox is a good might-have-been: oxygen's close boiling point to propane's melting point allowing common bulkheads, propane's self-pressurising nature, and the specific impulse and chilled bulk density being comparable to kerosene were attractive. The issues with clogging/corroding the fuel channels in the rocket nozzle were not. But maybe, with research money flowing in, they find out early that sub-chilling precipitates out the sulphur impurities that caused the damage. Or they literally plate the channels with gold.

Peroxide/kerosene would have made for a good 1st-stage booster that burns very cleanly, but the US has always been twitchy around high-test, 90-98% peroxide or HTP. Ask two different rocket scientists and you'll get three different opinions over how difficult it is to handle. In my humble opinion, it is far safer than the classic UMDH/N2O4.

-

Not saying you couldn't, but.

In RTLS, the timings are pretty strict. The sooner you flip and boostback burn to cancel out forward velocity, the closer you are to your landing site and the more reserve propellant you have to land. Or the less reserve propellant you need.

The booster is also going on a high trajectory so it's staging in a part of the atmosphere that's barely there. It is essentially a spaceship.

Figuring out when and how fast to flip this giant stick will have to be tested.

Edit: Batcrap idea - let it fly side-on for a bit to slow and then continue the flip a tad slower.

-

As I think SpaceX might have alluded to once or twice, they have a modest heavy-lift vehicle in the works. That would make for a fair delivery system for a SBSP system. It wouldn't even need to be that lightweight, so it could be constructed on the ground. Hell, take some domestic panels, add what shielding and hardening you think it might need, boost and see what breaks. Repeat a few times, and see if they work or they need to be built specially.

-

I can think of a reason: If a computer server is in orbit, it's a little harder for an authority - any authority - to shut it down.

-

How expensive will it be to fly an expendable SuperHeavy and a reusable StarShip? Say they don't crack hot-staging, the refurbishment turns out to be uneconomic or whatever. This is an inverse of the usual paradigm, but I'm throwing ideas around.

-

If we're bringing fiction in here, the Night's Dawn trilogy had combat wasps, missiles with computerised submunitions made to counter other combat wasps and I think DE.

-

Eager Space released this vid on how SS/SH, specifically designed to RTLS, stages differently from Falcon 9 and other rockets:

-

It does make it harder but... Go check out the presentation PDF I linked. In it there's a table of how long the laser beam is incident on the outgoing spacecraft and over what distance - a boost phase, in other words.

For the Earth-Moon boost, that's 6.8 hours and 10,000 km. For Mars, it's 1.2 hours and 30,000km. The spacecraft will then flip and be decelerated by a laser on the surface or in orbit. As I said, the deceleration hardware has to be sent on ahead. The electrical requirements are high but not onerous: 10 megawatts. E.g. the iROSA solar panel arrays on the ISS generate 20 kW and mass 325 kg. Fifty of those or similar would be gargantuan, yes, but it's mass you only have to take with you once. Or build with ISRU on the lunar surface. Mars would take a gigawatt nuclear reactor, but a nuclear-electric rocket/laser powerplant could self-deliver itself.

It does tickle me that these future PLTs follow near-torchship trajectories and literally have no brakes.

-

NASA is famous for hedging its bets. This falls under LIFT-1 and is just one technology demonstrator: https://blog.jatan.space/i/138608014/nasa-gets-serious-about-extracting-oxygen-on-the-moon

I suppose these days the consequences of using a fossilised resource are more apparent in everyone's mind. Extracting oxygen from the bare rock or soil, however, just leaves more metals. The yield of oxygen isn't bad either.

-

3 minutes ago, DDE said:

Yes. The stated future performance is when it can bounce the photons back and forth 10,000 times. Currently, it's roughly 1000 times or so, which at 6.6mN per kilowatt is still better than most solar sails and micro-thrusters, and for a much lesser opportunity and deployment cost.

There's nothing stopping you from encoding information into that laser both ways, either.

-

Not new news, but I found an interesting article about photonic laser thrusters and their potential to create a 'laser highway': https://spacesettlementprogress.com/enabling-a-multiplanetary-civilization-with-photonic-laser-thrusters/

Essentially, it uses a thin laser amplification medium and 99.99% reflective dielectric mirror on the powering spacecraft, with an identical mirror on the target spacecraft to bounce the laser light back and forth thousands of times, essentially turning it into a very long laser cavity itself. In the demonstration below a 500 watt infra-red laser, incident on a mock 750g cubesat, acts like a 500 kilowatt laser, with a measurable increase in thrust that pushes the satellite away and decelerates it. It's just 3.3 milliNewtons, but like a solar sail, this is continuous thrust that does not use propellant and has extremely high velocity.

Because I know people will ask, the researcher says it is "insensitive to mirror motions". I haven't been able to access the journal he cites, though. (Y.K. Bae, Journal of Propulsion and Power, Vol. 37, pp. 400-407 (2021))

The slides and audio on this presentation are available, and they propose that a small 1-ton spacecraft (50% of that payload) with a 30m mirror and a 10 MW laser could reach the Moon in 20 hours with a beam incidence time of 6.8 hours - a delta-V of 11.6 km/s. The same mass with a 50m mirror and a gigawatt laser could reach Mars in 18.5 days and an incidence time of 1.2 hours - a phenomenal 141 km/s (with an acceleration of 3.4 gravities!). It presumes you sent on another gigawatt laser ahead to Mars so you could slow down. Or use that Mars laser and a new probe to do a flyby of the asteroids in 6-18 days, or Jupiter and its moons in 45 days. Impressive.

It grew out of earlier research funded by NASA's NIAC, where the researcher was looking at formation-flying satellites that used laser light from the 'mother' or the 'flock' to move around in orbit. Thus one spacecraft could keep multiple others in orbit: https://www.nasa.gov/general/propellantless-spacecraft-formation-flying-and-maneuvering-with-photonic-laser-thrusters/

QuoteOur original emphasis was on propellant-free nanometer accuracy tethered formation flying, however, during our study on photon thruster demonstration, we discovered that our photon thruster (Photonic Laser Thruster, PLT) has a much larger potential in NASA mission applications than precision tethered formation flying. The potential resulted from a surprising discovery on the extraordinary stability of PLT against dynamic motions of mirrors in our unique active optical cavity, which may enable in space propulsion for an extremely wide range of unprecedented NASA missions. For example, 10,000 times recycling of photons with 15 kilo-watt input laser power, which can be delivered by a 100 kW solar panel would produce up to 1 N of photon thrust, which is sufficient to enable these missions.

-

NASA, in partnership with Sierra Space, has extracted oxygen from lunar soil simulant in a vacuum. This is interesting because not only did they perform this in a vacuum chamber, they attempted to simulate focused energy from a heliostat with a 15kW laser.

This has apparently bumped the TRL up to 6, and it's ready to be tested in space.

Science News Thread (for articles that don't relate to ongoing discussions)

in Science & Spaceflight

Posted · Edited by AckSed

It says to me, "We took the first person we could find in the office with Blender skills and told them to finish this render over the weekend."

The thing that makes me blink a bit is that this is supposed to be 100 metres tall. It can work, especially in Lunar gravity with no air, but if they pack all those collapsible booms, thin-film solar panels, electronics and lights on the top into the base, this is going to have the structural integrity of a crisp packet. It won't need more, but still.