DoctorEvo

-

Posts

474 -

Joined

-

Last visited

Never

Content Type

Profiles

Forums

Developer Articles

KSP2 Release Notes

Posts posted by DoctorEvo

-

-

Just made an attempt at this. Got all the way into the exact right orbit, after 2.5 hours. Ignited SRB, and it overheated and exploded a few seconds after ignition. >

>

> >

> >

>

I really should have read the earlier posts in the thread.....

Anyone want to explain WHY, without winglets, this happens? ???

Because someone thought it\'d be a good idea to model engine overheating. :

-

I\'d always read that part of the reason that they didn\'t use a standard one was because it had to include a flywheel that would spin the opposite way to prevent it from just spinning the operator in place an leaving the bolt still tightened down...

That flywheel would load up with angular momentum like a city tram in downtown Tokyo. I mean, it might be possible to unscrew a single bolt before it got COMPLETELY loaded up, but the power consumption would be insane, and after you get the bolt out, your flywheel would still be spinning until you found somewhere to dump all that momentum (perhaps... by screwing that same bolt back in again?).

Yeah, not practical. It\'s way easier to just anchor the tool (or more likely, yourself) to whatever module you\'re working on and transfer all that angular impulse directly back into the hull. Yet another reason why trying to work on something without directly or indirectly grappling to it is purely sci-fi level engineering.

Good thinking. At most, you\'d just need a red/green LED inside the suit so that you could confirm the pressure was equalized.

Probably not even. I mean, for the inside door, it\'d probably just flop open once pressure equalizes unless you had it latched closed. I\'d say that\'s pretty clearly indicative right there. The outside would be only slightly less pronounced, but you\'re still gonna know if there\'s any pressure still pushing on it if you use any sort of pressure-tightened latch (camlock, pressure-actuated locking pins, or a tapered detent).

Well, I wasn\'t thinking for HAZMAT reasons, but you originally suggested avoiding dust contamination of the component. Unless you had some method of positive-pressure to keep dust out of the box, you\'d need to enforce clean room conditions inside the pod, which would be a major pain in the ass for the astronaut...

I think you suggested that.

Anyways, the airlock is already going to need a circuit/valve bleeding air in to pressurize it, and I can\'t see it being that difficult to just add a filter to this and keep it running whenever the box was open.

Of course, most modern spacesuits have their own filtration systems (usually integrated into the scrubber circuit), and approach clean-room conditions anyways, so I didn\'t really think it\'d be an issue.

-

Very true! Still... I really do like the Gusmobile, it\'s a little sports car of a spacecraft, and it\'s hard to resist the thought of that kind of crew capacity and cargo volume in a vehicle with a mass no greater than that of the Apollo CSM! (Plus it would have brought back the Rogallo wing, so it might well have been made so that the reentry module was refurbishable and thus semi-reusable, too...)

And by my reckoning, would\'ve probably cost about half as much per launch as the Shuttle wound up costing, albeit with almost no parallel payload capacity. Sounds like Big-G would\'ve made a better schoolbus, but a worse pickup truck.

Sounds reasonable. I did manage to find that they had two separate gimbal motor sets for redundancy\'s sake, which seems a bit extravagant in terms of weight, but then, the CSM wasn\'t exactly designed to be as light as possible, was it?

Heh. Sounds like maybe another artifact of the direct-ascent lineage.

All that, and a zero-torque-on-the-wrist system? I WANT ONE OF THOSE IN MY TOOL BOX! It would make working on my Buick *so* much easier...

Zero torque on the wrist? No, I don\'t think so...

Sheesh, that\'d be hard to do. The best method I can think of right now is something that just friggin\' tack-welds itself to the spacecraft hull once you get it positioned, and that seems a little . . . yeah. Otherwise you\'d pretty much need either special fittings on EVERY SINGLE FASTENING PONT to index into, or give the tool its own dedicated RCS system (which is . . . yeah).

Mmm, good point. Actually, if we make it a cylindrical box (with hemispherical end, maybe, to make pressurization an even easier job?

We\'re talking like 5 PSI here. I think general handling and abuse is going to be a much bigger issue than the air pressure on our box\'s structure.

it could probably be done as a 'bayonet mount,' like many camera lenses--insert the end into the slots in the locking ring, twist clockwise 15 degrees (righty-tighty, remember!), and it locks into small detents in the locking ring to stay in place.

Yeah, I considered that. It is tidy and quick... but I feel like it\'s a no-exceptions two-handed job. A rock-in-and-latch deal could probably be manipulated with one hand.

I dunno, tough decision.

Include a small inflatable gasket that inflates as the first step of the pressurizing process, and you\'ve got a simple pressure-tight connection that can be easily made and broken

Too complicated. I\'m thinking just a simple, short (~1/2') plug seal (I picked a plug seal over say, a flat gasket seal to place more resistance load on the camlocks/detent when under pressure relative to when unpressurized), probably with the male end on the airlock.

and can be locked into place by the method involved in camera ones--a small spring-loaded pin that goes into a locking hole on the male side of the mount, which is disengaged by depressing a button on the box while twisting it.

I was thinking I\'d use airlock pressure rather than elastic pressure to engage any detent/camlock/locking pins, so that there\'d be (at the very least) a pronounced resistance to opening it while pressurized, which\'d be practically nonexistent while unpressurized. With as much plug-seal play and area and pressure as I was planning on, my camlock(s) could probably be configured such that their pressurized resistance was greater than could possibly be opened without depressurization. Of course, a dedicated pressure-switch-actuated locking pin would be even safer, but it\'d be more complicated as well (i.e. another thing to break, possibly leaving you with an awkward bulge stuck on your frontside).

In any case, having such tangible feedback built in (i.e. letting the user 'feel' the pressure state of the airlock) would eliminate the need for any special instrumentation to monitor airlock operation.

Of course, if we\'re going to have the ability to get the arms out of the sleeves, there\'d presumably be enough space to 'sit down' to get your hands into the glove box, so we might want to include a window to let you see what you\'re doing, plus a light to help with that. I\'m starting to think this box would end up being placed just above the beltline and take up a good chunk of the 'torso' of the pod. (Quick question--what do we do about the glove box gloves when the box isn\'t mounted, so they don\'t get in the way?)

Well, I wouldn\'t want the airlock hardware to consume any significant space when not in use, so I think a permanent 'HAZMAT-safe' barrier with some hokey little gloves poking through it would be out of the question. Maybe if there are concerns of possible HAZMAT contamination, you could put the part (and any tools and other associated bits) into a special transparent HAZMAT bag that you could work through before putting it in the airlock. Or you could just, y\'know, not bring it inside...

-

Plan: calculate exactly how much delta-V a single SRB with command pod and SAS has, get into whatever orbit has an orbital velocity of exactly that, and then use your SRB to stop dead right over the launch pad. You\'d need to time it perfectly, the orbit would probably be an insanely-high one, and it\'s very hard to be precise about when you are over the pad...

So basically exactly what Max did?

-

Granted, but V-2 guidance wouldn\'t have let you hit a specific city at that range. Be pretty embarassing if Ike had decided to order a massive attack, only to have all the weapons land out in farmland or uninhabited mountains or something, y\'know?

Ah, here we are...

It looks like the initial test articles for MX-774 used the simple gyroscopic guidance system similar to the V-2\'s, but Convair set out to develop the very same Azusa radar-tracking command guidance system that was eventually used on Atlas-D. So yes, it looks like they probably could\'ve had an intercontinental missile with a CEP on the order of five miles by 1950 - but still no warhead small enough to launch with it.

No, I\'ve seen actual motion picture footage of this one. It might be the same incident, though. I *will* say that the final result looked very similar to when the Air Force Museum\'s original Atlas sprang a leak and crumpled back in the 80s. (The one they have now is apparently modified for display with, essentially, a steel telephone pole up the middle to support it, so that it won\'t collapse no matter what.)

Ah, here it is: http://www.thespacereview.com/article/1326/1

Looks like this one\'s where it finally bursts...

Apparently there was a video, but it got pulled. In any case, the pictures tell the story pretty clearly.

THIS, I hadn\'t heard. It doesn\'t surprise me--I know how much force pressurization can exert--but that\'s one tale I hadn\'t heard. (At the same time, I can understand von Braun\'s skepticism--it was, at the time, a *very* radical concept, after all, and von Braun had an engineer\'s conservatism, taken to a bit of an extreme. as seen with his attitude towards LH2 as fuel...)

Yes, by Von Braun\'s standards, Bossart was clinically insane in more ways than one. He was, after all, one of the first proponents of LH2 propellants as well...

Oh, I bet I can guess what it was, now that I think of it. Atlas did use an early inertial/celestial guidance system. (In fact, I\'m not sure it even used celestial at all.)

Inertial/command. A interferometric radar ground station would track the rocket during launch and send updates to the rocket to make corrections. The military pushed for an independent fully-inertial system which was implemented in Atlas E and onwards, but the technology developed for the Azusa system saw continued usage in the spaceflight industry, with related ground-based tracking and command systems being the favored system right up to the Shuttle era, and even today to some extent (complimented by GPS and TDRS).

I suspect that they gave up on it with Atlas III simply because they felt that for a space launch booster that spends days or weeks vertical on the pad, the pressure-supported first stage was simply more potential trouble than it\'s worth, since there would be the requirement to keep it pressurized before--and during--fueling operations, which requires specialized (and expensive) ground equipment, etc. With the performance of the RD-170, they could get pretty much the same net performance with a non-pressure-supported structure.

They used an RD-180, not a 170. And performance is performance; adding extra weight that doesn\'t otherwise help performance is a performance penalty no matter what engine you have underneath.

As for the logistics, I think transportation and assembly are by far the more difficult aspect of handling balloon tanks than fueling is. For fueling, the fuel hoses are pressurized by pumps anyways, and I\'m sure pressure CAN be reduced on an Atlas even during on-pad fueling (maybe not down to the 5 PSI that they were stored at, but somewhere significantly less than the 25-30 PSI they launched with) if need be. Atlas already had all the systems for regulating pressure internally after fueling, so I can\'t see all that much extra external infrastructure being required to maintain pressure during fueling, aside from a pressure fitting on the nozzle-end of the fueling hoses. During transportation or assembly, on the other hand, the rocket\'s own pressure regulation systems are disabled and the rocket must be kept pressurized to 5+ PSI with nitrogen at all times. Now it\'s not terribly difficult to keep a steel balloon from leaking, but care must be taken not to open the wrong valve at the wrong time, and the pressure should probably be monitored during transportation.

SpaceX is right, though; if you can find some way to prevent the first stage from collapsing if pressure is lost (maybe some lightweight rigidizing elements that would allow the tanks to remain stable under 1G with partial pressure, or even ambient, but not enough for flight?), the weight reduction is dramatic. And, of course, using it on your top stage makes perfect sense, because the structural loads are probably about as low there as anywhere (less mass to support on top of it), and every pound shaved out of an upper stage trickles down to several pounds saved in the lower stages...

Oddly enough, the Falcon 1\'s second stage is not considered pressure-supported at all. Of course, being a pressure-fed stage rated for more than 135 PSI, the fuel tank itself is built heavily enough to completely eliminate any need for dedicated structural members at all anyways - pressurized or not. I sometimes wonder if this may be the answer - to simply increase the pressure rating of your fuel tanks so they can handle all assembly and pad loads unpressurized, and then re-assess your engine choice to see if the weight of the turbomachinery is really worth the ISP increase. (I mean, heck, the Kestrel, with a mere 135 PSI chamber pressure, achieves a vacuum ISP even better than Merlin does with its turbopump and 1000 PSI combustion pressure, just due to turbopump and nozzle losses!)

-

Fair point, though I expect that Convair would have had serious trouble with the guidance system before at least '53 or so, and the B-36's rather horrific engineering demands probably would have made it very hard for them to take that design study to a fully realized, buildable design before then, too, even if lightweight warheads were available.

It depends on your standards. A continent is a pretty big target. Obviously, V-2-level inertial guidance was available. With the thermonuclear warheads that WERE eventually developed, they could've caused plenty of devastation even with a poorly-guided missile.

I'll grant you that. I just meant that, at least as a *missile*, the balloon tanks got to be somewhat awkward; I wish I could find the YouTube video of one that was undergoing pre-fueling checks on the pad at Vandenberg, when one of the tanks sprung a leak and, in about 15 seconds, the whole thing had just sort of flopped over with the thrust structure still rigid on the pad, but the rest of the fuselage having banana'd. Very interesting footage, actually, and since they hadn't fueled it yet, there was no fire or explosion, just a crumpled and ruined booster.

I know the incident you're talking about. And I don't believe there is any motion footage of it, but the photo sequences I've seen do the job just fine. They were defuelling, and someone forgot to open a pressure valve. There was no leak. The balloon tanks were actually incredibly durable when pressurized - Bossart invited ABMA (including the very-skeptical Von Braun, who was known to had said of Mercury-Atlas astronauts that they deserve a medal just for having the bravery to SIT on top of one of Bossart's 'flimsy' rockets) to come and hit one of his fuel tanks with a sledgehammer. ABMA obliged, and the sledgehammer simply bounced back with such violence that it nearly maimed the technician who had taken the swing. The tank was completely unharmed.

Wasn't Titan I all-hypergolic like Titan II? If so, that'd reduce the response time once a missile was put on alert.

Ahahah. No. Titan I was semi-cryogenic. In fact, the LR-87 developed for the Titan is one of the few engines capable of burning RP-1, hypergolic, or liquid hydrogen propellants interchangeably with just a few modifications.

Huh, for some reason, I had always heard it took about four hours to prep an Atlas for launch. Must have been Atlas D and Atlas E, not Atlas F.

Atlas D and E both only took about fifteen minutes to elevate, fuel and fire from an alert state. Four hours may be the response time when not on-alert, though I have no idea what would take four hours to do. Then again, they say that the R-7 could take as much as twenty hours to prepare to launch...

Wow, never knew that. VERY light; I'd always thought that one of Titan's big advantages was the use of staging to let you drop the now-superfluous launch tankage.

Yeah. I never understood why they gave up on it with Atlas III - the performance is simply astounding. The original Atlas was in fact capable of performing true SSTO with a reduced payload. SpaceX seems to think it's a good idea, as the Falcon I uses a partially pressure-supported structure. And of course, Centaur sees continued usage as one of the best high-energy upper stages out there, and ACES will carry on the balloon-tank structure into the next generation of high-energy transfer stages.

-

I agree with that, DrEvo. In fact, it was the SRBs that were probably the most well-developed component of the Shuttle architecture, and they'd got the reusability of those down to a fine art.

Well...

But given they managed to get 20 or so flights on average out of SRB segments on average, I think there are some significant savings to be had in that area.

If they'd have forged ahead, It wouldn't have been hard to imagine the price of launching an American crew into space dropping below that of launching a Soyuz, especially if they'd have gone ahead with the re-usable Orion concept.

Maybe. Ares I and Orion both are far larger and heavier than Soyuz, being more closely-comparable to a Saturn I/Apollo in terms of scale. Thus it is probable that Ares I launches would remain somewhat more expensive than Soyuz launches, though probably with a much lower cost-per-kg on cargo missions, should it ever be used as such.

I know that I pointed to mass-production as being a better cost reduction method than reusability, but you can get some real benefits if you can make mass-produced parts re-usable, especially if you don't sacrifice ease of manufacture for it. In the Ares 1 system (as originally envisaged), the only parts of the system that you'd throw away would have been the relatively cheap upper stage and the expendable heat shield module.

Well development costs for reusable parts are slightly higher, purchase costs are substantially higher, but you get to use them for what would normally consume several expendable counterparts. For instance, let's say a Shuttle SRB costs about three times that of an equivalent expendable booster, but you get to reuse it about 20 times. Worth it, right? Unfortunately, it isn't THAT simple, as the costs of recovery and refurbishment and reloading are actually quite significant, but the potential for massive cost savings is there.

I'm very frustrated that Ares I isn't going to be completed; the system is extremely simple and could probably be flying inside of two years.

Two years? Seems pretty tight for NASA...

But yeah, as far as the contractors go, they could easily have everything ready to go by then.

However, I do recall that NASA determined, much to their chagrin, that it was going to have a payload to LEO a couple tons *less* than what the Orion MPCV would weigh, thus kind of making it superfluous, since it wouldn't be able to lift the vehicle it was designed for.

How did that happen? Did Orion turn out heavier than they initially planned?

Anyways, I can't see it being a terribly difficult thing to fix, since the second stage is all-new anyways and could probably be stretched to make up for it. (After all, it WAS stretched and contracted several times early on in the design process...)

(Still, if I were the contractor, I'd complete the development on my own to market as a commercial launcher; there's a lot of light payloads that would easily be within its capabilities, and the use of the RSRM first stage would probably let me get the price *way* down.)

Funny you should mention that... ATK isn't one to pass up such an opportunity: http://en.wikipedia.org/wiki/Liberty_(rocket)

Unfortunately, they didn't win a CCDev contract, and are a little pressed for funding now...

Interestingly, remember how everyone said that the SLS looked sort of like strapping SRBs to an S-V? Well, it turns out that the version everyone was seeing was the initial version, with 60-ton payload capacity and *no* upper stage, just the core stage and boosters. (I thought that I was seeing an upper stage beneath the spacecraft, but it turns out that no, there's just an adapter there.) The upper stage in the 'evolved' version will be the same diameter as the core stage, as tall as the spacecraft and adapter, and will increase payload to LEO to 130 tons.

Yep, I mentioned that.

If NASA switches to RS-68s or other expendable engines for the first stage, I could see the Initial SLS being made cost-effective as a heavy-lifter, but I suspect that the Evolved SLS will be limited to government use, since there's very little in the way of missions for a vehicle designed to put locomotives into orbit, except for putting up large space stations in a single launch, or launching spacecraft for exploring space *outside* earth orbit.

Well I, for one, am in FULL support of the development of an inter-maria high-speed-rail network on the Moon.

Nah, but really, I do feel that as the industry matures, costs will come down and the market will grow. It will be slow, but it will happen.

-

Oh, what could have been, huh?

Well, we eventually got the Shuttle, for what it's worth... ;D

I can't easily find any data on the gimbal limits of the SPS (but then, my Google-fu is weak), other than one reference to what looks like a chart showing the effective thrust at a one-second-of-arc angle--although that seems implausibly low, and it might be a case of someone mistranscribing a degree symbol as a double-quotation mark.

My Google-fu initially suggests 5 degrees.

Ah, makes sense. I hadn't seen anything on the driver since the very first Hubble repair mission in '93, so my memory is hazy at best--and probably outdated, too.

Oh yeah, I forgot the coolest part - an LCD screen with selectable torque and RPM settings.

Yeah. That's a nice design. I'd assume that the outer hatch would probably be on the top, instead of the front, so that one can more easily access it in the soft arm? (You might need to use a Boeing-style plug door as the outer hatch, the sort that opens inwards slightly, then pivots and slides outwards, to help keep it self-sealing when you're working inside the glove box...)

Well, if the airlock is modular, then you might not even NEED a dedicated outer door - perhaps just swing open the entire box to load/unload it. Latch it in place w/ object inside, pressurize it, knock on it some to make sure it's secure, and then open the inner door to grab the object. A safeguard for the outer door/unlatching the airlock makes sense... maybe some simple camlocks would suffice - designed such that their closed resistance becomes significantly greater if they are under pressure.

-

Well that's what we're talking about here, what i've been reading are saying 100-130ish for the SLS.

Yes, if you choose 25-50 it becomes quite economical, due to the fact there is demand for that payload. However again, we were never talking about that.

My point is, why the SLS instead of say, two falcon heavies?

Right NOW? Well I think the BIGGEST reason is because they've already put in so much into Ares and they don't want all that development to go to waste, and because a single-launch mission is much easier to coordinate. It is fairly unlikely the SLS will be very cost-effective unless they make some major changes to it.

However, I'm frankly kind of disappointed they didn't put their big dreams on hold for a while and go forward with the relatively modest Ares I, though. Even if it's just a small space taxi, it'd be enough to lift much of our dependence on the Russians for the ISS program, and it actually has the potential to be very cost effective.

-

Major pros:

Quickness -- Atlas's simple staging design (see below) made it so that it could be ready for service much sooner than its competition, the Titan series. Due to the fears of a 'missile gap' after Sputnik, this was a HUGE issue for the US military, and that alone guaranteed that Atlas would be built and enter service.

That, and Convair was much better-versed with rocketry than their competitors were, having designed a true ICBM as early as 1946, but not having built it since warheads were not yet small enough to be launched by one.

Difficulty of handling -- The very balloon tanks that allowed the Atlas to complete its mission made it extremely difficult to work with, because if it was vertical and the tanks were not pressurized, the whole booster would crumple over like it was made out of tinfoil. (I can't find it right now, but I've seen video of just that happening to one that was being prepped for a test launch from Vandenberg in the 60s.) Most variants escaped that by being based in 'coffin' shelters, where they were stored horizontally before being erected for launch, but that just exacerbated the next issue.

It's still immensely easier to handle than something that needs to be assembled and transported vertically.

Slow response time -- This was probably the single biggest flaw of the Atlas as an ICBM. Even the final versions that were intended to be stored vertically in silos could not be launched rapidly; they had to be winched up out of the silo(!) to the surface, then they had to be fueled before they could launch.

The same was true of Titan I. Atlas F was, for all intents and purposes, equivalent to Titan I in terms of response and survivability. Earlier, horizontally-stored Atlases were only marginally slower, but their coffins had lower survivability and fuelling had to be done outside of the coffin with no protection whatsoever.

The entire procedure took about five hours, one hour to raise the missile and then four to fuel it. Unlike Titan, with its 'storable' hypergolic propellants, the Atlas could not be stored ready-to-fire; the kerosene fuel could be left onboard, but the liquid oxygen oxidizer had to be stored elsewhere so that it wouldn't boil off. At best, an Atlas could be kept on 'hair-trigger' alert, fully fueled and ready to go, for about 24 hours before the LOX boiled off to the point of needing replenishment. (Ironically, this same flaw as a weapon made it excellently suited for a space launch vehicle, since the semi-cryogenic propellant mix had a better specific impulse than either the Titan-style hypergols, or the Minuteman-style solid fuels.)

Atlas F could be kept on alert in-silo for prolonged periods with the kerosene tank full. From this point, it could be fuelled with LOX (in-silo to enhance survivability), elevated out and fired in the span of ten minutes. That's every bit as good as Titan I.

Poor mass fraction -- Despite the use of jettisonable 'half-stage' boosters to provide most of the thrust at launch, and the use of balloon tankage to reduce structural weight, the fundamental reason that the Atlas ended up being eventually supplanted by Titan in both missile and space launch roles (Atlas I, that is--Atlas II was a major redesign, and Atlas IV and V are completely different vehicles) was that the lack of true staging meant that the booster had to lug a lot of extra weight all the way to the end of the flight. Once Titan had demonstrated that staging and airstart of liquid-fuel engines was feasible, that allowed a much better percentage of fuel versus total weight compared to the stage-and-a-half design, resulting in better payload from a given engine.

Oddly enough, they concluded that attempting to divide Atlas, with its lightweight balloon tanks, into two separate stages without stretching would actually negatively effect performance due to the added dead weight - it was actually better to carry all that tankage with you than to bother figuring out how to leave some of it behind. In fact, they later went EVEN FURTHER with the stretched Atlas H. You gotta admit, those balloon tanks were LIGHT.

When it comes down to it, the Titan's biggest advantage over Atlas was raw muscle - bigger, taller, heavier... Atlas really never stood a chance.

-

Atlas is very comparable to R-7 (the rocket that Soyuz is launched by) in many ways. The Mercury spacecraft was obviously quite a bit smaller and more primitive than Soyuz, but the rockets are similar in terms of performance, cost, growth, etc.

Cons

Specialization. Because the Soyuz is so specialized, it can't really do much more than act as a ferry for crews to and from the Space Station (even though Soyuz was designed with a lunar mission in mind, it would have taken a specially redesigned version of the craft to do it). It is not able to launch anything other than cosmonauts and [a very small amount of] personal gear, and it can't act as a work platform.

Dude, have you NEVER heard of Progress or Fregat?

-

Given that situation, where you're just doing a quickie turnaround for a small number of flights before a more detailed turnaround, *that* I could see being feasible, the same way that it is for airliners and military airplanes, particularly if you work out a reliable MTBF figure for all the quick-change sealed-black-box systems and use that minus one mission to schedule their being swapped out with a new/refurb unit. (For example, 'OK, the APUs have an MTBF of about 20 hours. They're usually on for four hours per flight, so just to be safe, we'll swap them out every fourth flight even if there haven't been any problems.')

Yes, that was pretty much the idea. However, MTBF is usually not used to define replacement intervals, but rather inspection intervals, with parts being replaced as needed - that is, whenever they fail, or whenever they pass certain margins, depending on how critical they are. After Challenger, though, they refused to take ANY chances - even though the vast majority of their measures were completely unrelated to the cause of the disaster.

-

. . . unless it's manufactured to specs provided by NASA, in which they carefully design the program to avoid economies of scale. In which case a big rocket is also hideously expensive.

Well, bluntly put, yes, that can be the case.

Um, can you point out to me the 100t+ to orbit large rockets which actually have realized the cheap cost per kg?

Like i said, politics and bureaucracy gets in the way of engineering all the time, gotta learn to deal with it though.

100t+? There are all of TWO rockets with that kind of payload, and of them, Energia was the closest - and it was only ever launched twice, before political turmoil caused its cancellation. The N1 was close, and it WAS actually a fairly inexpensive rocket given its size.

But if you choose a more reasonable and diverse criterion - say, 25 or 50 tons - you start to see some very successful rockets with excellent costs-per-kg. If you can use reasonable building practices and avoid building above your means, you CAN achieve fairly good economics by simply up-scaling.

There does come a point of diminishing returns--look at Wiki's list of launch systems and their cost-per-kilo to LEO. (http://en.wikipedia.org/wiki/Comparison_of_orbital_launch_systems) For example, RSA's Strela (basically, a UR-100!) can put 1700 kg into LEO for five million euros, so about $10 million; the Saturn V could put 118,000 kg into LEO, but adjusted for inflation, would have cost about $1.1 billion. For the same price, you could launch 110 Strelas and put 187,000 kg into LEO. I expect that there's a happy medium somewhere in between that'd cost less than either, but it's still interesting.

Well, we've been over the reasons Saturn was expensive before. Currently, the 'happy medium' you're talking about seems to lie in the neighborhood of 50 tons (with Proton and soon the Falcon Heavy leading the pack), but it WILL grow as the industry grows.

See above. In that situation, there'd be no reason to use the Saturn unless you had some very heavy component that needed to be put into orbit in a single piece--unless you wanted to avoid flying assembly missions, so that you could assemble and test the entire vehicle on the ground rather than having to do EVAs to make the final connections.

Yes, well, there is the factor of how a one-piece spacecraft will probably weigh much less than a modular design assembled from 50 components, but I'm ignoring that for now because it's a little hard to estimate HOW much heavier modular designs would be.

I do like the EOR/LOR scheme you proposed before, though - where the ultimate plan is to reuse already-launched hardware several times without recovery. That would most likely have a major impact on the average costs-per-mission, especially for low-mass-fraction components.

-

In NASA's defense, they *did* discover that parts that should have been replaced and/or refurbished were flying again after falling outside the specified tolerance bands, and that would be in violation of all practices in the aviation industry. Frankly, the shuttle was *far* too complex a vehicle to acheive a sustainable turnaround rate of less than roughly 20 weeks, I expect.

Yes, but I'm not talking about 'sustained turnaround rates.' I'm talking about maybe checking some of the more reliable or less-critical parts maybe, every third or fifth launch. Of course, certain parts will need to be swapped or inspected every flight, but many components can be trusted to survive multiple launches, especially if they aren't critical. And if you DO find parts that are wearing well past tolerance during the inspection intervals, you can shorten those respective inspection intervals, and lengthen intervals for components which are not wearing as fast as expected.

If you stay rational about such issues instead of completely flipping out when something goes wrong (or, on the other hand, being complacent and ignoring problems outright), you can actually maintain a healthy balance between safety and utility.

Really, the only way you're going to make a sustainable turnaround rate for a reusable spacecraft that's less than about 16 weeks would be if you made most of the systems be sealed 'black boxes' that, after each flight, you just pulled out of the spacecraft for inspection and refurb, then installed new/refurbished ones off the shelf for the next flight.

Why every flight? You don't trust an APU or a hydraulic pump to work for more than a single flight in a row? If you distrust your hardware THAT much, then you have no place in such a high-stakes endeavor in the first place.

It's worth noting that many catastrophic mechanical failures in the aerospace industry are human error, caused by careless or hurried maintenance. Sometimes there are actual SAFETY-ORIENTED reasons for choosing the less-frequent, more-deliberate inspection and maintenance schedules, lest someone slip up and leave a rag in your turbopump after their hundredth time disassembling and inspecting it.

If you can do sealed-box system unit swapouts with some sort of simple, standard connection--which military aircraft have been doing since about 1980--you *might* be able to actually meet DoD's spec for Shuttle turnaround, if you have a huge amount of manpower to do it. But those sorts of modular systems are heavier than ones directly integrated into the vehicle, and since dead weight is a killer for any spacecraft...

I don't think so. Replacing stuff takes time. I'm pretty sure the 2-week turnaround consisted of just replacing the components that were actually broken, assembling the stack, rolling it out, and launching. Like I said, there was no illusion of being able to sustain such ludicrous launch rates. Extensive inspections WOULD be required at some point, resulting in a sustained launch rate MUCH lower than this shortest-possible turnaround time.

-

Doc, I will point out that EOR may have certain cost advantages, too, if the price-per-mass of the smaller boosters is enough lower to compensate for the cost of flying multiple launches and flying assembly missions, particularly as economies of scale kick in on the production side. (Part of the reason the Saturn V was so expensive was that there was so little demand to spread out its development cost over, while smaller boosters can be sold to many more customers and thus spread their sunk costs out a great deal more, after all.)

That'd be just fine, except the opposite is almost universally true - larger rockets achieve a much lower cost-per-kg to orbit.

Add in the cruel nature of the rocket equation, and there does come a time when on-orbit assembly of the spacecraft begins to make sense as you pass the point of diminishing returns on your heavy-lifter. (I expect that's going to turn out to be somewhere in the range of 100-200 metric tons to LEO payload capacity, unless there's some radical new development that allows for some vast increase in heavy-lift efficiency--perhaps once fusion gets working well enough to allow a nuclear *fusion* thermal rocket, as opposed to a fission-thermal rocket.)

Well between launching a rocket that's 5 times larger once or launching five smaller rockets into the same orbit, the bigger rocket is almost always cheaper. The only reason to use multiple smaller rockets over one bigger one is if the payloads need to be placed into their own orbits.

-

How long was the turn around times on the shuttle pre accident era?

DoD specified two weeks. The fastest they actually performed was eight weeks. The fastest achieved post-Challenger was thirteen weeks, and the idea of deferring any inspections for one turnaround was considered unacceptable - they just flipped and decided that all the sudden they had to check absolutely everything, absolutely every time.

Note that turnaround time is not a sustained launch rate (well, at least not in the initial pre-Challenger case). The sustained launch rate was somewhat slower, initially limited by external tank production to 24 per year for the entire fleet. Of course, even with a four-orbiter fleet, the slow turnaround rate caused by the expanded post-Challenger safety measures easily drowned this limitation. IF they somehow sustained that thirteen-week turnaround for the entire four-orbiter fleet (not possible given that the Orbiter Processing Facility isn't capable of handling four orbiters at once), they'd still only manage 16 launches per year.

-

Hey, good to see you back, I was afraid the Routing Monster had eaten you or something...

Heh, school, and I decided to go active again with Incredibots too... but yeah, I'm probably not going to be posting as frequently for a while. This discussion is too interesting to disengage from altogether, though.

They had designs that would have mated with the standard Apollo SLA (or even an Apollo SM--McDonnell, understandably, tried to downplay *that* option!), the Titan III, and directly to the top of the S-IVB, apparently. If they went with the full S-IVB... damn, that's a hell of a lot of volume they'd have there.

Sheesh... that's like, 7 meters I think? Yeah, no wonder they figured could squeeze more crew than the shuttle!

The LM ascent stage *did* use that technique, though. I believe the SPS had pretty limited gimbal range, too, so that even if the gimbal system failed, you could still conduct a successful TEI burn with RCS steering.

Well, naturally. The RCS WAS rated to steer the whole stack, so there's no reason it shouldn't be able to steer it under thrust unless the CG is just WAAAY out. Heck, if it was in-trim enough that you only needed 50% of maximum RCS authority, you could get away with firing aft-RCS only and suffer virtually no propellant waste over a gimbaled burn.

I ran the numbers earlier and I think I figured about half a degree of SPS gimbal equates to a 100% RCS-couple duty cycle. So yes, I guess gimbaling would present considerably more control authority than the 100-lb thrusters alone.

I think the other reason you might do that is to clear out the smoke and fumes after the fire is out.

Yeah, it would be the best way to purge everything. Even the fire retardants themselves have the potential to be irritant. That can wait, though.

Ah, I wasn't sure on that. For some reason, I thought they used separate drills with fixed heads.

Well, from what I can find, it looks like the driver they use has a chuck for interchangeable heads, so I can only assume they actually use it. Apparently it uses NiMH batteries and has a special skinny handle and trigger for gloved usage, too.

Most likely. ...you might be able to pull off the modular box that's worn only when needed, but you'd need to have a permanent pressure hatch on the inside on the pod in that case.

Naturally. Internal-opening, about 75-150 in2 in area... should be enough to keep it from being opened prematurely. And if the airlock comes unsecured during pressurization, at least the inside door will still be closed.

-

Which we don't, and I still wouldn't yet put good money on this rocket ever getting to the pad (but would be pleasantly surprised if it did)

And, sure, a single large rocket, rocket vs rocket, might be the way to go, but I think once you take all the bureaucracy and politics into it (and, unfortunately, those are things that always need to be taken into account), maybe not

Well if you can't pull it together enough to start building the proper hardware, you can bet you aren't going to pull off an interplanetary exploration program.

Oh well just tether up a few of those resupply pods to it, add some boosters and away she goes ;P

Boosters?

I'm sold.

-

PROS

Shuttle: Semi-reusable, fast-turnaround, EXTREMELY large crew capacity, heavy-lift capability, potential to be very cost-effective for frequent launches. Gentle reentry with wide crossrange capability.

Saturn V: Super-heavy lift capacity, solid safety record. Minimal primary development costs.

Soyuz: Proven R-7 rocket, simple and cheap horizontal assembly, well-evolved spacecraft with extremely low-weight construction, very low per-launch costs.

Shenzou: Similar to Soyuz spacecraft in many respects. Low cost.

N1: Heavy-lift capability. Horizontal assembly.

CONS

Shuttle: High initial development and production costs. Lack of comprehensive launch-abort modes; labor-intensive post-Challenger safety measures crippled the program in nearly every respect. Requires considerable (but mostly pre-existing from Apollo) infrastructure to launch. Difficult to fill its payload capacity given its restricted launch inclinations.

Saturn V: Very high production costs for an expendable vehicle. Difficult vertical assembly required. Considerable new infrastructure (VAB, cryogenic fuel production) required. Difficult to make use of its superheavy payload capacity.

Soyuz: Fairly low lift capacity. (Can be seen as a good thing in some ways, given the extremely-low per-launch costs).

Shenzou: Long March rocket uses slow vertical-assembly and has a questionable safety record. Low payload.

N1: Abysmal launch record. Complex design.

Is this for manned rockets only?

-

Actually, it's quite a bit different. This is closer to an SRB-equipped version of the Saturn INT-20 (http://astronautix.com/lvs/satint20.htm) or the Saturn 2SL/120' SRB variant of the Saturn INT-18 (http://astronautix.com/lvs/satint18.htm) design studies. In terms of size, it's closer to the INT-20, but designwise, it's more like the INT-18, using hydrogen in the first stage instead of kerosene.

I'd say that there's more than enough disparity here to say that this rocket is NOT a member of the Saturn family whatsoever. It's pretty solidly Shuttle-derived. The resemblance is purely aesthetic.

Really, the only part that's directly comparable to any of the Saturn designs would be the upper stage, which looks to be very close to the S-IVB, except it'd have to be scaled up, since the Apollo CSM had a diameter of 3.9 meters, while the Orion CSM that this is designed for has a diameter of 5 meters.

You know that's just an adapter, right? The S-IVB itself was entirely cylindrical and 20 feet around at both ends. With a different adapter, an S-IVB would mate just fine to Orion without scaling.

Besides, the EDS is shuttle-ET based anyways, so I think it's safe to assume it'll be considerably wider and more squat than S-IVB.

I think the biggest reason it 'looks' like a Saturn V is that it has similar roll patterns on it...

Exactly.

And when they run out after seven launches, they're going to have to start buying new ones. Simply put, there's a bunch of good reasons *not* to use the SSME in anything that's not reusable; that's just the biggest one. (How about having to do a Flight Readiness Firing pre-launch 'engine test' before *every flight*?)

Well that's kinda fallacious... the same is true of pretty much all expendable engines as well. Viking is the only liquid engine I'm aware of that is regularly flown without being test-fired first. Otherwise, you're gonna have to turn to solid-fuelled engines if you wanna have that sort of launch flexibility.

The cost issue is clearly by far the most significant. It does seem rather silly to use SSMEs in an expendable manner.

But will it be the new Constellation/Venturestar/NASP/...?

Probably.

Why are they using the RS-25's for the first stage? Better off just modifying an RS-68 to make it man rated. Twice the thrust with half the complexity. Could probably ditch the SRB's too if they did...

Performance. RS-68s use a wasteful gas-generator cycle, similar to that of the Apollo-era J-2s. They also have a lower thrust:weight ratio than both the SSMEs and the J-2, which in my opinion is inexcusable for a simple gas-generator engine, especially considering how recently the RS-68 was designed. All this amounts to a sizable performance hit in terms of payload-to-orbit. Omitting the boosters would be out of the question. The fact that you could get away with using only three of them is peanuts when you consider that three of them would still weigh almost double that of five SSMEs.

All said, though, it might be worth taking the performance hit just for the sake of cost savings. First stages are big and expensive, and looking for cheaper, heavier, less-efficient solutions (for instance, SRBs) is a very reasonable thing to do (unlike on upper stages, where the costs of excess weight trickles down to lower stages as well).

I agree, although man-rating the RS-68 is far from a trivial operation. There were (last time I checked) 200 changes that need to be made in order to leave the RS-68 suitable for man-rating.

Beauracracy. That's all I have to say.

Incidentally, can anyone explain to me the difference between the SLS and the Areas V? As far as I can see the difference is entirely political . . .

They're both Shuttle-derived, but there are a few significant differences. For one thing, unlike SLS, Ares V was not man-rated. It was expected to be used in tandem with the man-rated Ares I, a much smaller and very distinct (SRB-derived) rocket. Ares V was two stages (plus boosters) only, whereas SLS is planned to be single-stage plus boosters for most low-orbit missions, and two-stage only for higher or heavier missions.

But yes, in the two-stage configuration, SLS is very similar to Ares V, and the whole thing is rife with politics.

It seemed petty when they switched away from Bush’s returning to the moon. I think Obama has changed the long term goal to Mars instead.

Huh? I don't think so. Constellation had a faint inkling of possible interplanetary missions in the distant future that *might* be possible but probably won't happen, while SLS doesn't seem to have any notion of leaving Earth orbit at all.

The biggest problem I have with that move is it feels more like an accomplishment for the sake of accomplishing. No doubt the whole space race started with those ideals, but I want long term-sustained exploration where the main goal is for the benefit of scientific study, and not just to go there for a few missions and never return. Permanent moon exploration/occupancy is the next logical step from having a permanently manned space station.

The problem with that is that robotic space exploration can already do everything manned exploration can and more. If your goal is only science, then manned exploration is obsolete.

Didn't they understand that putting people, not Kerbals, on top of a rocket that has solid motors anywhere outside the LES is a BAD IDEA? .....

Why? The LES doesn't care what's behind it. It'll pull you away from boosters or liquids or a silo of irradiated nitroglycerin all the same.

SRBs are not the problem. A missing exit-strategy is the problem.

On that point, what is with the focus on Single rocket to the moon/mars etc?

Why can't NASA just use say, one of the regular heavy lift rockets to assemble a craft in orbit (say at the ISS) then use a soyuz (or spacex if they get that far) to ferry the astronaughts up. Heck, you could even make the craft a reusable one minus the crew reentry pod..

Because Earth-Orbit Rendezvous is just a crutch for when you don't have a rocket big enough to do the job in one shot.

Wait, why don't we just send the ISS to mars?

Oh jeez.

I don't think even the ISS has enough consumables for the whole trip there and back. Maybe with a single crewman.

Anyways, I think there's one thing above all that needs to be said about this rocket:

[shadow=red,left]IT NEEDS MORE BOOSTERS.[/shadow]

-

If the peak possible tumble rates were higher than the LES was qualified for, it'd require at least one new qualification test to make sure it'd pull the CM free into a safe condition for recovery system deployment at those rates. After all, if the shorter stack could tumble such that the parachute shroud lines could end up wrapped around the CM, it'd be a very bad day for the crew in an abort. (In other words, it's about what effect the shorter SM would have on the potential peak tumble rates of the complete stack, not what effect it'd have on the LES performance.)

Hmm. Well in that case, a shorter SM would have LESS lateral forces on it, thus causing an INCREASE in aerodynamic stability...

Of course, the reduced mass would shift the CG aft as well (destabilizing things), but this shouldn't be significant for either S-IC or S-II flight phases, and S-IVB flight is wholly exoatmospheric, and the LES has dropped by then anyways.

There is the issue of moments of inertia, but I don't know what to make of that. Again, I think it'd be insignificant until S-IVB flight.

Heh. Actually, the drawings on Encyclopedia Astronautica shows it having a *lot* more internal volume than you might expect, even in the twelve-man configuration. Then again, as small and light as the Gusmobile was, you've got a *lot* of extra volume and mass when you enlarge it to mate with an S-IVB...

A WHOLE S-IVB, or a tapered adapter like Apollo had?

Ironically, other than the pintle mounting, the ascent engine was basically a scaled-down version of the SPS engine; they were both built for 100% reliability with no more moving parts than absolutely necessary. (Two, on the ascent engine--ball valves for the hydrazine and N2O4.)

There's a reason Glushko had a hardon for hypergols...

I believe it was, for two simple reasons. First, due to the asymmetric sector assignments of the SM, the center of mass would shift during flight, and, indeed, during the burns. Second, starting about 20 seconds after S-II ignition, the SPS became the abort motor, and for that, you'd need more control authority than you could get from the RCS alone, for detumbling after separation.

Hmm. I always figured gimbaled engines as a replacement for dedicated aft-facing vernier thrusters, not as a supplement. But I guess chuffing away with your RCS to keep your wonky-loaded CSM lined up isn't quite as efficient as gimbaling... (still, I wonder how much weight they could've saved from it... eh, I guess up-rating the thrusters for abort probably would largely defeat that purpose)

But Soyuz's engine doesn't gimbal, I know that much.

It was either for the Earth survey, or somehow related to the solar mission. I've seen the photo of Area 51 that the Skylab 4 crew got into trouble for taking, and it's pretty lousy--there were already better images of it in public NASA archives from other Earth-survey missions, so espionage wasn't going to be all that do-able.

I don't see how that could help at all with solar observation... unless they were listening for radio noise and were trying to maximize their time over radio-quiet extreme Southern latitudes...

Given the exertion involved in an EVA, I can also see wanting to have a bit of extra margin for safety.

Yes, but I wonder if the extra exertion from the extra pressure might defeat the purpose...

Meh, probably not.

Also, I worked it out, and alveolar ppO2 at sea level is 2.7 PSI delivered when waste-gas dilution is taken into account. Thus, the ACTUAL pure-oxygen pressure needed to match this would be 4.4 PSI absolute.

Well, it's the last-resort firefighting option on every spacecraft I know of. It's not ideal, but if all else fails, opening the cabin vent *will* put out the fire...

Not necessarily. Some stuff burns just fine in a vacuum. And odds are, if displacing the oxygen away from it doesn't do it (ESPECIALLY in the presence of a fire suppressant), evacuating the chamber won't either.

I was thinking more of it being like a classic socket set, where you've got one drive with interchangeable bits/heads that can be swapped out as needed. Given the need for the drive to be a zero-net-torque one in a microgravity environment, this could make life a lot simpler for the EVA crew instead of having to carry a dozen drivers.

I thought they pretty much already carried a regular socket set... one hand drill, and a bunch of heads for it.

I think a hand drill is more simple and modular than a fixed 'R2-D2' deal.

That... will be a tough nut to crack.

I dunno, I'm still leaning towards the front. It just seems like it'd be too difficult trying to move tiny fiddly parts too far away from that cozy space right in front of you with unwieldy pressure gloves.

Heh, did you see the lunar rover planned for Constellation? It was going to have a pressurized cabin, and *no* airlock, per se... instead, the EVA suits would have a back hatch for entry, and lock onto the aft hatches of the cabin, so they'd stay outside the cabin, but with entry from inside. They might well be willing to look into something along those lines for spacecraft not intended for atmospheric entry...

Hmm.

I think some sketches are in order.

Yes, but shipping containers generally aren't *dragged* around on skids; they're either carried around on a crane or forklift, or on a wheeled chassis. Harder to move on skids, after all. Actually, if you could equip it with proper carrier slings, a large forklift might be a good choice for handling an S-II; 40-foot containers are frequently handled that way in container ports.

There we go. Do they really have forklifts that big?

That might actually be more problematic than near a road; rail clearances are pretty rigid. Honestly, the best option might be landing it right by some sort of port or beach where it could be loaded directly onto a Ro/Ro ship. (Hmm, would an S-II have fit into a war-surplus LST?)

No... I don't think it'd fit through the doors of an LST. Probably not a RORO either. There might be a FEW ROROs with wide-enough doors, but your average RORO won't cut it.

I'm thinking maybe land it near a river and then just load it onto a barge.

-

Eh, four tanks is isn't that long a stack, but you'd have flip trouble with just a solid up top.

O'course, you could compromise; three tanks above, three tanks each below, strut the bottom three together, apply winglets. R8s should give you the control authority to correct tricoupler roll and to spare. =/

I almost did that, but with a SINGLE tank below, because that would let me mount the winglets even lower so that they overlapped the engines some. But this is what I went with, and it worked, so eh.

-

Why the long tank stack on the rocket, Evo, instead of putting them under the tricoupler? Balance?

Yup, and structural. This way I could use less winglets and I didn't have to worry about three long stacks wobbling around and crashing into each other.

Though there were some odd lengthwise wobbles in response to having control inputs way out on the ends of such a skinny stack...

-

[cont'd]

(Interestingly, indications are that fire on-orbit would be pretty much a non-event, due to the lack of convection in a microgravity environment--the fire would tend to form a little spherical ball and, when it's used up the oxygen in that ball, snuff itself out. Even with ventilation fans running over it, it appears that the lack of convection would greatly slow the progress of any fire, and basically result in it smoldering instead of bursting into flames!

Well that's convenient...

Not to mention that, worst-case scenario, you put a couple people in EVA suits in the cabin, stuff everyone else in the airlock and seal it, then depressurize the cabin. Poof, no more fire. Cool whatever's burning to prevent reignition, repressurize, and away you go to a precautionary early landing.)

Do you know how long it takes to put on a space suit? Don't bother depressurizing; if you simply displace the oxygen with halon or CO2, all you need is a simple O2 respirator to go back in and start your cleanup. Much faster response, much better damage control. Frantically decompressing chambers to stop a fire is just asking for a Soyuz-11 repeat - not to mention your couple of suit-clad space-firefighters are just BEGGING for an embolism.

Oh, certainly. In fact, you might even make the arms hardsuit ones, so that you could use *them* as 'third hands' to remain holding onto something whilst doing something inside the suit, by simply locking down the joints.

That'd be pretty handy if you could get it to work right. Have full hardsuits ever been tested in a vacuum before? I kinda wonder if the pressure might cause unwanted breakout friction that might make fine movements difficult. The bearings are a tough point too, since the fact that they must be completely circular necessitates a bulky design (and the biggest reason why hard gloves are simply impossible), though that's not nearly as big an issue with our pod concept here.

What about one of each? A clampable hardsuit arm on the right, and a soft arm on the left for when you need to reach through a tight spot or whatever.

However, foot-end 'grapple claws' that can be actuated by a foot switch might be useful for certain tethering applications, or towing large objects with maneuvering thrusters, if you need to move something to an area where there's no RMS access.

I guess. I can't see how they could do anything a simple tether couldn't, though. But I guess you'd need to be able to REACH your feet in order to connect a tether to them, huh?

Though now that I think about it, it might be useful to have a retractable rotary tool with socket wrench-style interchangeable heads mounted on top of one hand, to replace the need to carry a hand tool to turn screws, nuts, and bolts during EVA; just put on the appropriate bit, extend the shank, place it on the bolt, and press one button to turn clockwise, the other to turn counterclockwise.

Heh, nah. It's like my dad always tells me when I try to hold more than one tool at once instead of walking back to the toolchest: don't cripple yourself with tools you don't need. Is it THAT inconvenient to carry a driver in a pouch near your belt?

Nice idea! That'd help a *lot* for fiddly little parts; even if they have to be kept in a dust-free environment (meaning they stay in a glove box inside the pod), glove box gloves are a *lot* easier to work in than EVA gloves.

I thought so. What I'm not sure about is where to put such an airlock. The front would be the most accessible place of course, but then you'd have to compromise between size and obstructiveness (unless you made it a modular, external chamber you could just clamp on when you need it...)

Y'know, we oughta try working up a rough design idea and see about patenting it, so we can then sell the idea to NASA and RSA...

Heh. Somehow I doubt they're too eager to buy something that won't fit in their airlocks. Not yet, anyways.

SpaceX, as good as they are, do have a bit of the 1960-61 'Space Cowboy' mentality going, given the number of times they've had a pre-ignition pad abort and basically went out and kicked it until it started working again, then proceeded with launch. ;P Not that I don't think a bit of that is a good thing--particularly in the early phases of a program, to help get funding by boosting reliability numbers--but I really think the recoverable upper stage on the Falcon 9 is a pipe dream of rainbows and unicorn farts, at least with their planned TPS. Still, can't hurt to try it, and if it *does* work, well, more power to 'em. Even if it only works about 25% of the time, that'd still allow a reduction in operating costs.

Well, they SHOULD be able to recover the first stage, no problem. They have no delusions of reusing EVERYTHING - it sounds like their plan is to recover what they can, look at what got destroyed, decide if its worth protecting next time or just replacing, and making the appropriate changes. Given that 10-40% of the mass of an uncontrolled satellite reentry typically reaches the surface, they should be able to get at least SOMETHING back - even if it's just a few bits of hardware here and there. Everything's marinized already, so reentry's the only concern they're currently exploring - first the lower stage, THEN looking at adding the systems to recover the upper stage.

And cork actually might make a decent TPS; it should ablate well (for its weight, anyways), it WILL insulate well, and as long as it doesn't disintegrate too quickly from the pressure and heat (the insulation should help with that somewhat), it could theoretically be up to the task if you used enough of it.

I was more worried about the tugs required. I've got a friend who was a maintenance guy in the Air Force, and he's told tales of the time he needed to tow a fully-loaded KC-135 with an F-350 pickup truck, because all the tugs were broken. The only reason he didn't burn out the clutch completely is that it had an automatic transmission, and with the throttle floored, he hit a top speed of two miles per hour. That's with free-rolling wheels, mind you. I'm pretty sure the KC-135, at max gross, weighs more than an empty S-II, but it'd have a lot less static resistance than landing skids. Dragging it off the runway wouldn't work very well if you needed the Crawler-Transporter to get it moving, after all.

An F-350 weighs around three or four tons. A typical commercial aircraft tug weighs around fifty tons, with a towbar capacity of thirty tons (keep in mind tugs have to deal with not only rolling friction, but inclined slopes as well). An empty S-II weighs about fifteen tons. The maximum gross weight of a typical twenty-foot shipping container is thirty tons. Equipment capable of moving an empty S-II is far from uncommon.

Well, Edwards is flatter than most deserts--dry lake bed and all that--

Does that look like a dry lakebed to you!?

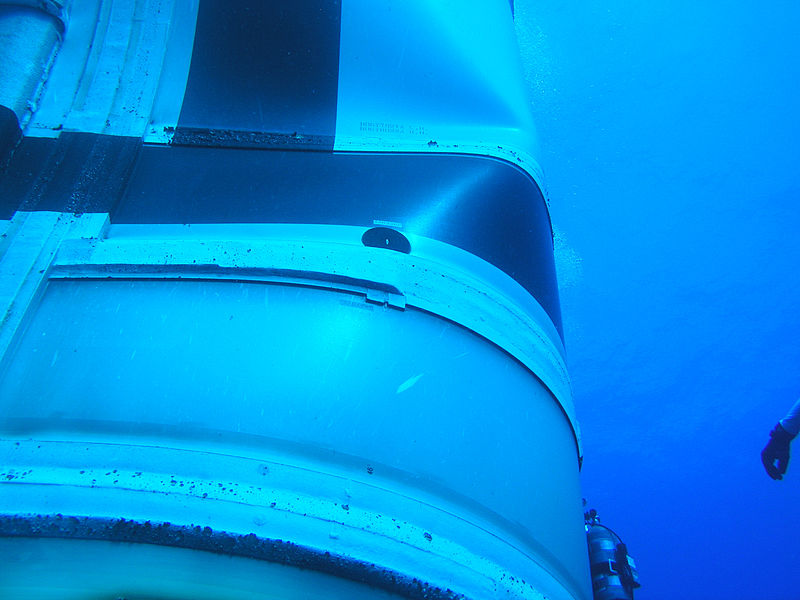

Here, have a closer look:

and I was just also thinking of having the infrastructure there to secure the stage after landing, and to move whatever transportation method is going to be used to get it back to the Cape.

Well, there's something to be said for that...

How about landing it next to a railway?

We will not weaponize space

in KSP1 Challenges & Mission ideas

Posted

Oh, boy, do NOT get me started on those arrogant windbags. >